SIDDHIVINAYAK STEEL CORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SIDDHIVINAYAK STEEL CORPORATION

Cold Work Tool Steel

COLD WORK steels fall into five groups: water hardening, oil hardening, medium alloy air hardening, high carbon-high chromium and shock resisting. As their name implies, these steels are used in low to medium temperature applications. Highly wear resistant due to the high volume of carbides in the microstructure.

The high carbon and chromium content promotes deep hardening. Hardenability is accentuated by small amounts of tungsten and molybdenum. Dimensional change in hardening is extremely low.

Typical uses are long run blanking, stamping, and cold forming dies; lamination dies; thread rolling dies; trimmer dies; slitters; brick mold liners; Work Rolls.

FOLLOWING GRADES ARE AVAILABLE : D-2 (1.2379),D-3 ( 1.2080) OHNS, EN-31 .

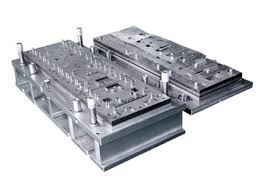

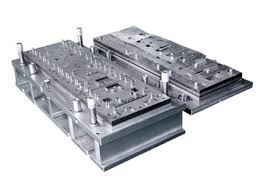

Plastic Moulding Tool Steel

Description / Specification of Plastic Moulding Tool Steel

We are involved in offering a wide range of Plastic Moulding Tool Steel to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Plastic Moulding Tool Steel. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

High Speed Tool Steel

HIGH SPEED steels have been named to show their ability to resist softening at elevated temperatures therefore maintaining a sharp cutting edge when cuts are heavy and speeds are high. They are the most highly alloyed of all of the tool steel types. They normally contain comparatively large amounts of tungsten or molybdenum, chromium, Cobalt and vanadium, along with carbon. FOLLOWING GRADES ARE AVAILABLE : M-2 (1.3343),M-35 (1.3243), M-42, T-1, T-2.

Hot Work Tool Steel

HOT WORK steels, as their name implies, are used where operating temperatures of the tool may reach levels where resistance to softening, heat checking and shock is important. It has high heat resistance and medium wear resistance, Distortion in hardening is low.

This group of steels is excellent for such uses as die-casting dies, extrusion dies, plastic molding dies, hot forging dies, hot gripper and heading dies, hot mandrels, hot work punches, and hot shear knives.

following grades are available : H-13 ( 1.2344) H-11 ( 1.2343 ) H-21 ( 1.2581 ) 1.2714.

Beryllium Copper

Beryllium Copper is a copper alloy with the optimum combination of mechanical and physical properties such as tensile strength, fatigue strength, performance under elevated temperatures, electrical conductivity, bending formability and corrosion resistance.

Beryllium Copper is widely used as contact springs in various applications like connectors, switches, relays, etc. we offers a variety of Beryllium Copper alloys in several tempers to cover different applications. Our Beryllium Copper products are available in strip, plate, rod and wire forms.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.